The hospitality industry from time immemorial has been a significant part of every society because of its indispensable role in providing comfortable shelter for travellers and residents. These services mostly come in an exotic or modest setting, which is proportional to the need and financial capacity of the individual.

With the daily increase in the need for more industry players, there is a corresponding rise in the demand for quality, which sets every player to their heels to seek the best approach to improving their services and infrastructure.

One of the crucial aspects of consideration is furniture quality, emphasizing the kind of foam used for upholstery. It is important to note that the comfort of any hotel furniture is derived from a mixture of certain qualities. By default, one must consider any of the following tips when picking the suitable foam for their hotel furniture:

With the daily increase in the need for more industry players, there is a corresponding rise in the demand for quality, which sets every player to their heels to seek the best approach to improving their services and infrastructure.

One of the crucial aspects of consideration is furniture quality, emphasizing the kind of foam used for upholstery. It is important to note that the comfort of any hotel furniture is derived from a mixture of certain qualities. By default, one must consider any of the following tips when picking the suitable foam for their hotel furniture:

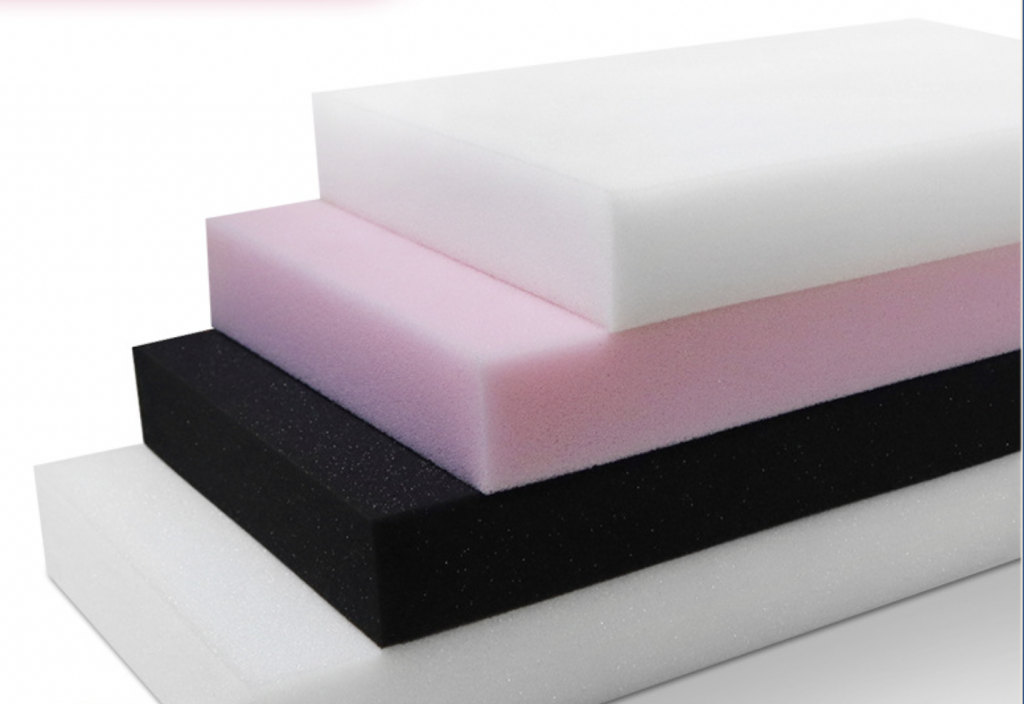

Classification of sponges

There are many types of sponges used in finished furniture, including foam, shaped foam, rubber foam, recycled sponge, etc.

There are many types of sponges used in finished furniture, including foam, shaped foam, rubber foam, recycled sponge, etc.

1、Foam

This material is formed with polyether foam, like foam bread. It can be foamed by mechanical equipment or manually surrounded by wooden boards, and the foam is like a large square-shaped loaf of bread, using a slicing machine after the slicing process, cutting thickness according to different requirements, and the softness and hardness of the foam can also be adjusted.

Seat foam is generally used 25 to 28kg/m3, other 20 to 22kg/m3 density (sofa standards have clear requirements for these two indicators).

Sponge softness and density although there is a direct relationship, but with different additives formula also has a relationship, so the industry is divided into high elasticity, grey super, black and grey super, soft cotton. Product design should be used depending on the different shapes, structures for reasonable scientific collocation, generally divided into the upper, middle and lower three parts with different elasticity, density of the sponge. There is a sponge called fire-resistant cotton material (flame retardant cotton), in fact, before the sponge foam, the material formula to add fire retardant, such as chlorine, bromine so that the sponge on fire can produce fire smoke, to play a flame retardant role (flame retardant sponge may be an important aspect of flame retardant furniture, after all, today are high-rise buildings, there is an ordinary sponge burning very instantaneous).

Foam is most common in furniture, sofas and upholstered beds used in the sponge is basically foam. The applicable testing standard for foam is GB/T 10802-2006 General purpose flexible polyether-based polyurethane foam.

This material is formed with polyether foam, like foam bread. It can be foamed by mechanical equipment or manually surrounded by wooden boards, and the foam is like a large square-shaped loaf of bread, using a slicing machine after the slicing process, cutting thickness according to different requirements, and the softness and hardness of the foam can also be adjusted.

Seat foam is generally used 25 to 28kg/m3, other 20 to 22kg/m3 density (sofa standards have clear requirements for these two indicators).

Sponge softness and density although there is a direct relationship, but with different additives formula also has a relationship, so the industry is divided into high elasticity, grey super, black and grey super, soft cotton. Product design should be used depending on the different shapes, structures for reasonable scientific collocation, generally divided into the upper, middle and lower three parts with different elasticity, density of the sponge. There is a sponge called fire-resistant cotton material (flame retardant cotton), in fact, before the sponge foam, the material formula to add fire retardant, such as chlorine, bromine so that the sponge on fire can produce fire smoke, to play a flame retardant role (flame retardant sponge may be an important aspect of flame retardant furniture, after all, today are high-rise buildings, there is an ordinary sponge burning very instantaneous).

Foam is most common in furniture, sofas and upholstered beds used in the sponge is basically foam. The applicable testing standard for foam is GB/T 10802-2006 General purpose flexible polyether-based polyurethane foam.

2、Shaped foam

This material foam by polyurethane material, by the foaming agent and other additives mixed, pressure agent into a simple mold heating can be pressed out of different shapes of the sponge, it is suitable for swivel sofa seat, back cotton, there are also a small number of armrests also use shaped cotton to do. The use of 55# ~ 60# material density (high density and high quality, relatively good compression), its elasticity is more in line with the relevant national standards. Sponge elasticity hardness can be adjusted, depending on the different parts of the product to adjust. General seat cotton is harder and denser, back cotton is the second, pillow cotton is softer.

Office chairs, auditorium chairs or other stereotyped furniture basically used for the sponge for the stereotyped cotton. The basic characteristic of these furniture is the high frequency of use and therefore the density of the sponge required is also higher.

Shaping foam

This material foam by polyurethane material, by the foaming agent and other additives mixed, pressure agent into a simple mold heating can be pressed out of different shapes of the sponge, it is suitable for swivel sofa seat, back cotton, there are also a small number of armrests also use shaped cotton to do. The use of 55# ~ 60# material density (high density and high quality, relatively good compression), its elasticity is more in line with the relevant national standards. Sponge elasticity hardness can be adjusted, depending on the different parts of the product to adjust. General seat cotton is harder and denser, back cotton is the second, pillow cotton is softer.

Office chairs, auditorium chairs or other stereotyped furniture basically used for the sponge for the stereotyped cotton. The basic characteristic of these furniture is the high frequency of use and therefore the density of the sponge required is also higher.

Shaping foam

3、Rubber foam

It is also a kind of sponge, it uses the main material is natural latex raw material foam, it has rubber characteristics, excellent elasticity, good resilience, will not be deformed, but the price is not expensive, 3 to 4 times higher than the foam cotton.

Recycled spongeThis material is often used in latex mattresses and latex pillows (often sold on the market as a selling point).

Rubber wool

The three types of cotton mentioned above are ordered from highest to lowest price: rubber cotton, shaped cotton and foamed cotton. From here it is also clear that foamed cotton is the most commonly used.

It is also a kind of sponge, it uses the main material is natural latex raw material foam, it has rubber characteristics, excellent elasticity, good resilience, will not be deformed, but the price is not expensive, 3 to 4 times higher than the foam cotton.

Recycled spongeThis material is often used in latex mattresses and latex pillows (often sold on the market as a selling point).

Rubber wool

The three types of cotton mentioned above are ordered from highest to lowest price: rubber cotton, shaped cotton and foamed cotton. From here it is also clear that foamed cotton is the most commonly used.

4、Recycle sponge

Furniture products have a kind of called “recycled cotton”, in fact, it is sponge shredded extrusion and made. The cost is very low, but the elasticity is very poor, the density varies.

Some cheap net red chairs and stools soft package often use some scrap material sponge bonding molding, is the sponge edge material chopped bonding molding.

Furniture products have a kind of called “recycled cotton”, in fact, it is sponge shredded extrusion and made. The cost is very low, but the elasticity is very poor, the density varies.

Some cheap net red chairs and stools soft package often use some scrap material sponge bonding molding, is the sponge edge material chopped bonding molding.

How to choose the right foam for furniture?

Formation and Composition of the Foam

The foam composition is vital to consider when picking your hotel furniture. A solidly built foam with structured layers aids in boosting the level of comfort the foam gives. Moreover, a more substantial bottom layer with a soft covering is a good composition.

The Thickness of the Foam

Foam thickness can also be referred to as the depth of the foam. It is an essential ingredient to look out for in picking foam because, for foams, a thicker layer is said to be more comfortable.

The Toughness of the Foam

The structural formulation of foam is also a vital player in the comfort level a foam brings. The foam layer doesn’t need to be as hard as a rock; however, it should be padded with a firm wooden platform or springs to maximize comfort to end-users.

Foam Density Variations

The importance of foam density can not be overemphasized as it has a close relationship to the performance and efficiency of the foam. Therefore all hotel managers and foam shoppers must always take note of the varying foam densities.

First off, one can obtain the thickness of the foam through the division of two parameters. For example, if the weight (in pounds) of a layer of foam is 150 pounds and the foam measures a total of 30 cubic feet, the density of the foam would be 150 pounds divided by 30 cubic feet, which would be equal to 5 PCF (per cubic feet).

Consequently, for memory foams, the range for a low density is 0-3PCF, having a medium PCF at 3-5(PCF) and a high-density rating of 5 and above PCF.

While for polyfoams, the range for a low density is 0 – 1.5PCF, having a medium PCF at 1.5 – 1.7(PCF), and finally a high-density rating of 1.7 PCF and above.

Formation and Composition of the Foam

The foam composition is vital to consider when picking your hotel furniture. A solidly built foam with structured layers aids in boosting the level of comfort the foam gives. Moreover, a more substantial bottom layer with a soft covering is a good composition.

The Thickness of the Foam

Foam thickness can also be referred to as the depth of the foam. It is an essential ingredient to look out for in picking foam because, for foams, a thicker layer is said to be more comfortable.

The Toughness of the Foam

The structural formulation of foam is also a vital player in the comfort level a foam brings. The foam layer doesn’t need to be as hard as a rock; however, it should be padded with a firm wooden platform or springs to maximize comfort to end-users.

Foam Density Variations

The importance of foam density can not be overemphasized as it has a close relationship to the performance and efficiency of the foam. Therefore all hotel managers and foam shoppers must always take note of the varying foam densities.

First off, one can obtain the thickness of the foam through the division of two parameters. For example, if the weight (in pounds) of a layer of foam is 150 pounds and the foam measures a total of 30 cubic feet, the density of the foam would be 150 pounds divided by 30 cubic feet, which would be equal to 5 PCF (per cubic feet).

Consequently, for memory foams, the range for a low density is 0-3PCF, having a medium PCF at 3-5(PCF) and a high-density rating of 5 and above PCF.

While for polyfoams, the range for a low density is 0 – 1.5PCF, having a medium PCF at 1.5 – 1.7(PCF), and finally a high-density rating of 1.7 PCF and above.

Foam Variations in Various Hotel Furniture

Interestingly, the difference between high, medium and low PCFs of foams depends on the foams’ material composition. So when shopping for foam, one must take note of the type of foam rather than giving all the attention to the density rating alone. Conversely, it is wise to go for different foam densities depending on how suitable they fit in other hotel furniture.

Intriguingly, high-density memory foams and Polyfoams are firmer compared to low-density foam. They are more suitable for hotel dining cushions and parlor cushions by default.

Medium-density latex foams are also suitable for chair cushions, especially in the reception or waiting corner. They give a remarkable feeling when you rest on them.

On the other hand, low-density memory foams are best for hotel mattresses since they feel less stiff and are great for relaxation after a stressful day.

Interestingly, the difference between high, medium and low PCFs of foams depends on the foams’ material composition. So when shopping for foam, one must take note of the type of foam rather than giving all the attention to the density rating alone. Conversely, it is wise to go for different foam densities depending on how suitable they fit in other hotel furniture.

Intriguingly, high-density memory foams and Polyfoams are firmer compared to low-density foam. They are more suitable for hotel dining cushions and parlor cushions by default.

Medium-density latex foams are also suitable for chair cushions, especially in the reception or waiting corner. They give a remarkable feeling when you rest on them.

On the other hand, low-density memory foams are best for hotel mattresses since they feel less stiff and are great for relaxation after a stressful day.

High Resilience Quality

When considering the quality of foam for hotel furniture, it is vital to take note of the level of resilience the foam has. Foams measuring 2.8lb – 3.0 lb per ft3 are one of the best sets for cushions. It has a quick reversal time frame, making it responsive after applied pressure is released. Interestingly, it also provides an extra bounce.

High resilience foams precede others significantly when leveraging comfort and lasting value. They are best for sofa cushions. Like the hospitality industry, these kinds of foams are also used in upholstering cushions found in yachts, government offices, and wealthy private homes. The least qualifying high resilience foam is measured at 2.5lb per cubic ft for the record.

So, having talked about these tips, let’s dive to check out a few foams that are excellent for hotel furniture.

When considering the quality of foam for hotel furniture, it is vital to take note of the level of resilience the foam has. Foams measuring 2.8lb – 3.0 lb per ft3 are one of the best sets for cushions. It has a quick reversal time frame, making it responsive after applied pressure is released. Interestingly, it also provides an extra bounce.

High resilience foams precede others significantly when leveraging comfort and lasting value. They are best for sofa cushions. Like the hospitality industry, these kinds of foams are also used in upholstering cushions found in yachts, government offices, and wealthy private homes. The least qualifying high resilience foam is measured at 2.5lb per cubic ft for the record.

So, having talked about these tips, let’s dive to check out a few foams that are excellent for hotel furniture.

Good Quality Foam for Hotel Furniture – Lux Foam

The Lux foam is one of the leading foams used for upholstering hotel furniture- this is so because of its firmness. It is above the industrial-grade foam found in average cushions worldwide. Hotel furniture is almost in use every day, and since most people are gripped with the fear of tears and wear, it is best to use foams with high resilience for hotel furniture.

For a fact, Lux foam is an ideal foam because of its heavy and firm internal structure. The hotel management would adequately utilize the resources invested in purchasing foams like this, and the value of money invested continuously multiplied. The Lux foam has a sporadically high resilience quality, which means that it often simultaneously returns to its original shape immediately after compression. Surprisingly, it has a lasting value of approximately seven years.

The Lux foam is one of the leading foams used for upholstering hotel furniture- this is so because of its firmness. It is above the industrial-grade foam found in average cushions worldwide. Hotel furniture is almost in use every day, and since most people are gripped with the fear of tears and wear, it is best to use foams with high resilience for hotel furniture.

For a fact, Lux foam is an ideal foam because of its heavy and firm internal structure. The hotel management would adequately utilize the resources invested in purchasing foams like this, and the value of money invested continuously multiplied. The Lux foam has a sporadically high resilience quality, which means that it often simultaneously returns to its original shape immediately after compression. Surprisingly, it has a lasting value of approximately seven years.

Conclusion

The hospitality industry is a vital part of any society, with a good reward level to the industry’s direct and indirect players. With such a high prospect in this 21st century, key players must carefully consider the innovation, style, and quality of hotel infrastructure, especially in the foam used in upholstering hotel furniture.

It is undoubtedly true that the sprouting of innovations simultaneously induces a paradigm shift from the utilization of old facilities. However, hotel managers should move with the flow of innovation or risk reclining down the echelon.

The hospitality industry is a vital part of any society, with a good reward level to the industry’s direct and indirect players. With such a high prospect in this 21st century, key players must carefully consider the innovation, style, and quality of hotel infrastructure, especially in the foam used in upholstering hotel furniture.

It is undoubtedly true that the sprouting of innovations simultaneously induces a paradigm shift from the utilization of old facilities. However, hotel managers should move with the flow of innovation or risk reclining down the echelon.